3D Modeling and Reverse Engineering

3D modelling is the process of creating a digital representation of a physical object. This can be done using a variety of methods, such as 3D scanning, photogrammetry, and computer-aided design (CAD). 3D models can be used for a variety of purposes, such as product design, manufacturing, and animation. Reverse engineering is the process of taking a product apart and analysing it to understand how it works and how it was made. This information can then be used to create a new product, improve an existing product, or simply learn more about how things work.

With the increasing popularity of 3D Laser Scanning (LIDAR), we have been developing workflows for As-Built 3D Modelling of just about any Existing Object. Having a Computer Programmer on-site enables us to quickly write Custom Software Tools to Analyse Point Cloud of complex 3D Objects.

We offer 3D Modelling options with most of our own survey work, but we also provide this service to anyone with a Laser Scanner or those in possession of Point Cloud Data. Simply upload your Point Cloud Data to an FTP Server like Dropbox, and we will give you a quote to produce a 3D Model and/or Fabrication Drawings of the Object(s).

3D Modelling

CNC Tooling

Reverse Engineering

Deformation Analysis

3D Modelling and Reverse Engineering

3D modelling is the process of creating a digital representation of a physical object. This can be done using a variety of methods, such as 3D scanning, photogrammetry, and computer-aided design (CAD). 3D models can be used for a variety of purposes, such as product design, manufacturing, and animation. Reverse engineering is the process of taking a product apart and analysing it to understand how it works and how it was made. This information can then be used to create a new product, improve an existing product, or simply learn more about how things work.

With the increasing popularity of 3D Laser Scanning (LIDAR), we have been developing workflows for As-Built 3D Modelling of just about any Existing Object. Having a Computer Programmer on-site enables us to quickly write Custom Software Tools to Analyse Point Cloud of complex 3D Objects.

We offer 3D Modelling options with most of our own survey work, but we also provide this service to anyone with a Laser Scanner or those in possession of Point Cloud Data. Simply upload your Point Cloud Data to an FTP Server like Dropbox, and we will give you a quote to produce a 3D Model and/or Fabrication Drawings of the Object(s).

3D Modelling

CNC Tooling

Deformation Analysis

Reverse Engineering

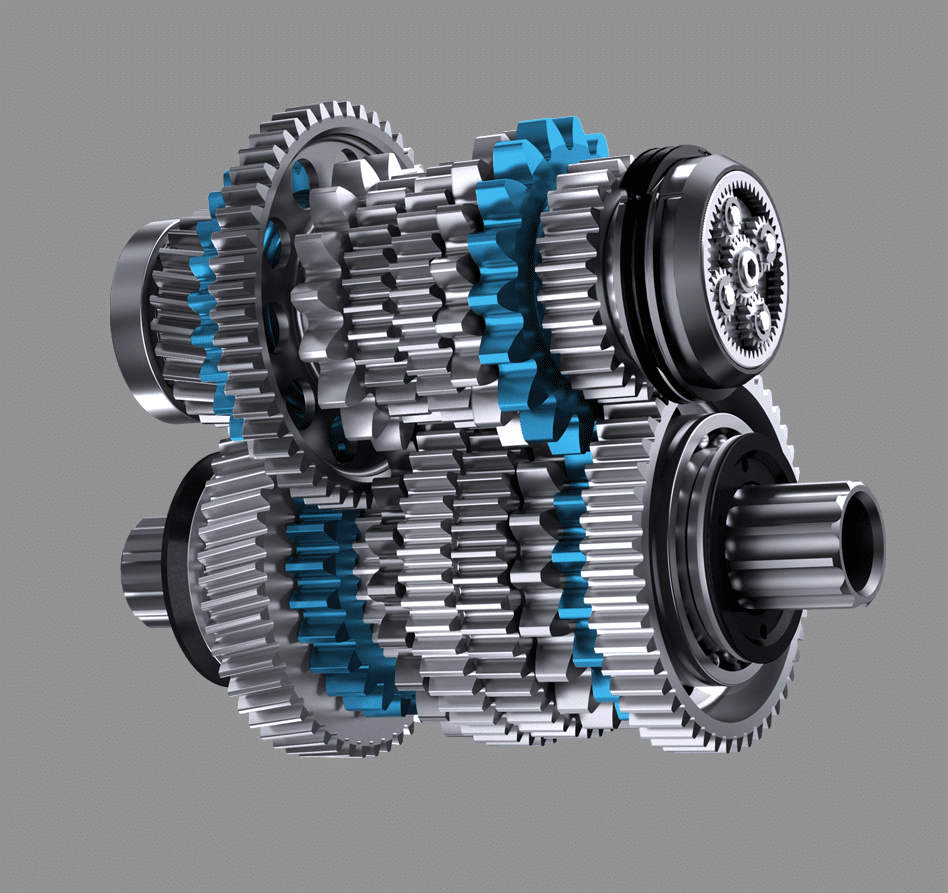

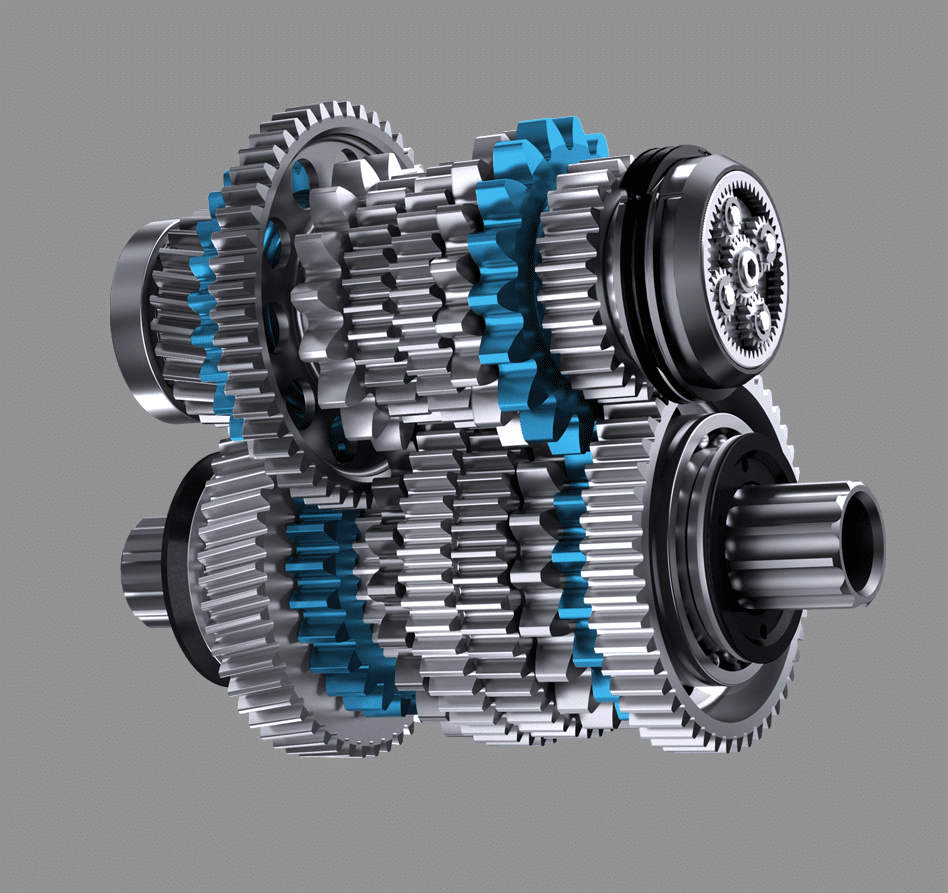

3D Solid Modelling

We specialize in creating 3D models of real-world objects from point cloud data. This challenging task requires us to use a variety of CAD packages and develop libraries of standard objects for the plant, structural steel, buildings (BIM), and other industries. With enough geometric information, we can model any object as a solid, no matter its size or complexity. Our expertise enables us to create highly accurate and detailed models that can be used for a variety of purposes, such as product design, manufacturing, construction, and asset management. We understand that the needs of every client are different, and we work closely with our clients to understand their specific requirements and develop solutions that meet those needs. Please contact us if you need help creating a 3D model of any object. We would be happy to discuss your needs and provide you with a custom solution.

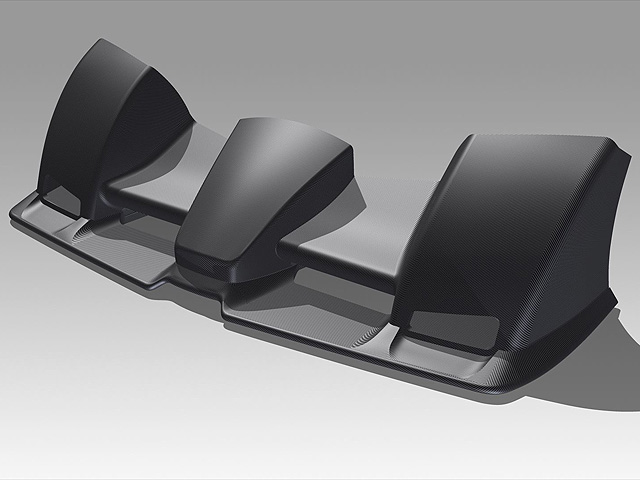

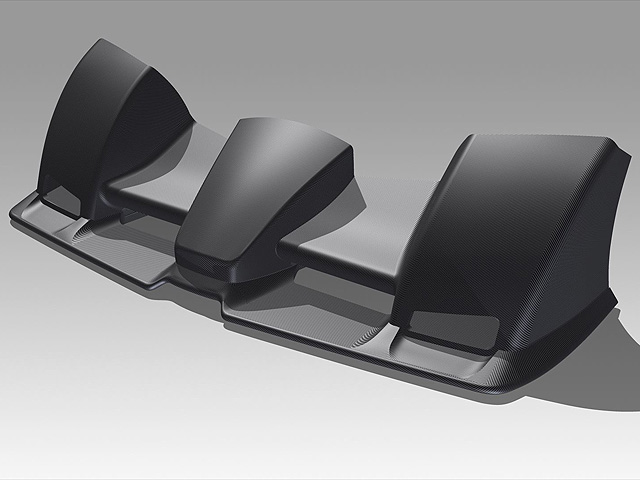

CNC Tooling, and 3D Surface Modelling

CGS excels in 3D modelling of industrial plants from scan data, delivering unparalleled accuracy and fidelity. Our expertise lies in creating highly detailed representations of complex facilities, with a meticulous focus on every detail. Through advanced project management, we ensure that our comprehensive data structures align perfectly with your requirements. Our 3D models are tailored to your project’s specific needs, guaranteeing exceptional results that exceed your expectations. Our commitment to quality and customer service is evident in every aspect of our work. We work closely with our clients to understand their specific needs and develop solutions that meet those needs. We also offer a wide range of value-added services, such as 3D scanning, point cloud analysis, and custom software development. Whether you need a 3D model of a new plant or an existing facility, CGS can help.

3D Solid Modelling

We specialize in creating 3D models of real-world objects from point cloud data. This challenging task requires us to use a variety of CAD packages and develop libraries of standard objects for the plant, structural steel, buildings (BIM), and other industries. With enough geometric information, we can model any object as a solid, no matter its size or complexity. Our expertise enables us to create highly accurate and detailed models that can be used for a variety of purposes, such as product design, manufacturing, construction, and asset management. We understand that the needs of every client are different, and we work closely with our clients to understand their specific requirements and develop solutions that meet those needs. Please contact us if you need help creating a 3D model of any object. We would be happy to discuss your needs and provide you with a custom solution.

CNC Tooling, and 3D Surface Modelling

CGS excels in 3D modelling of industrial plants from scan data, delivering unparalleled accuracy and fidelity. Our expertise lies in creating highly detailed representations of complex facilities, with a meticulous focus on every detail. Through advanced project management, we ensure that our comprehensive data structures align perfectly with your requirements. Our 3D models are tailored to your project’s specific needs, guaranteeing exceptional results that exceed your expectations. Our commitment to quality and customer service is evident in every aspect of our work. We work closely with our clients to understand their specific needs and develop solutions that meet those needs. We also offer a wide range of value-added services, such as 3D scanning, point cloud analysis, and custom software development. Whether you need a 3D model of a new plant or an existing facility, CGS can help.

Reverse Engineering

With extensive experience in automotive design, manufacturing, and assembly, we excel at solving complex 3D problems. We regularly collaborate with companies in 3D printing, CNC milling, yacht design, automotive design, tooling, and mold making, which has sharpened our skills and enabled us to develop efficient solutions to a wide range of challenges. Our team of experienced engineers and designers is passionate about helping our clients to achieve their business goals. We work closely with our clients to understand their specific needs and develop custom solutions that meet those needs. We also offer a wide range of value-added services, such as 3D scanning, point cloud analysis, and custom software development.

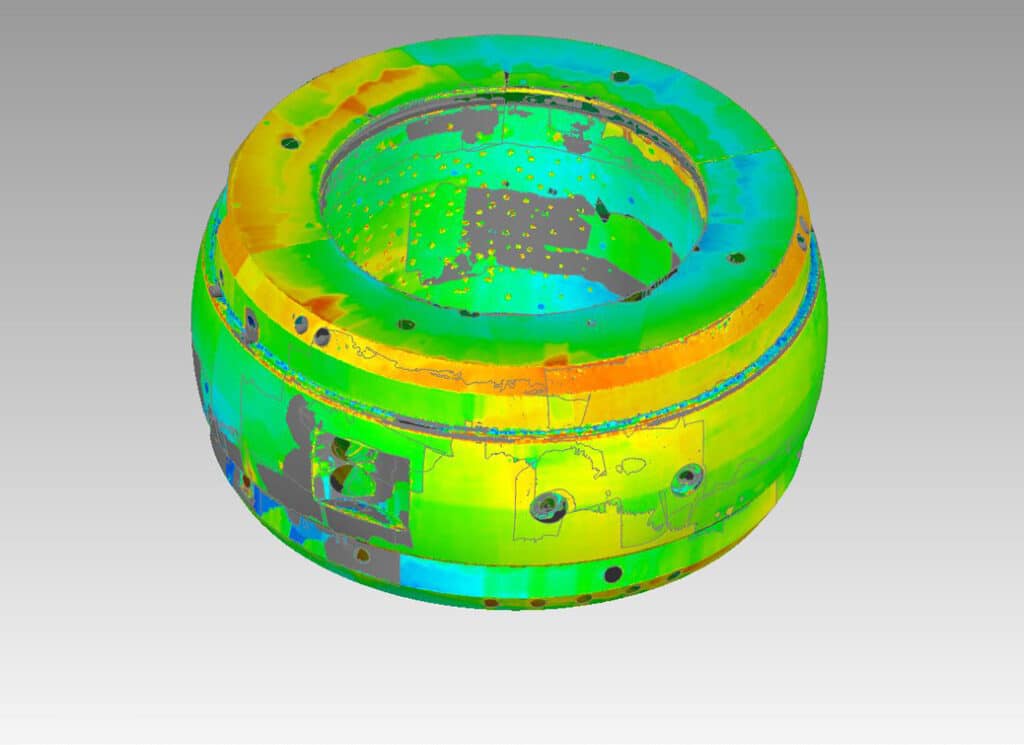

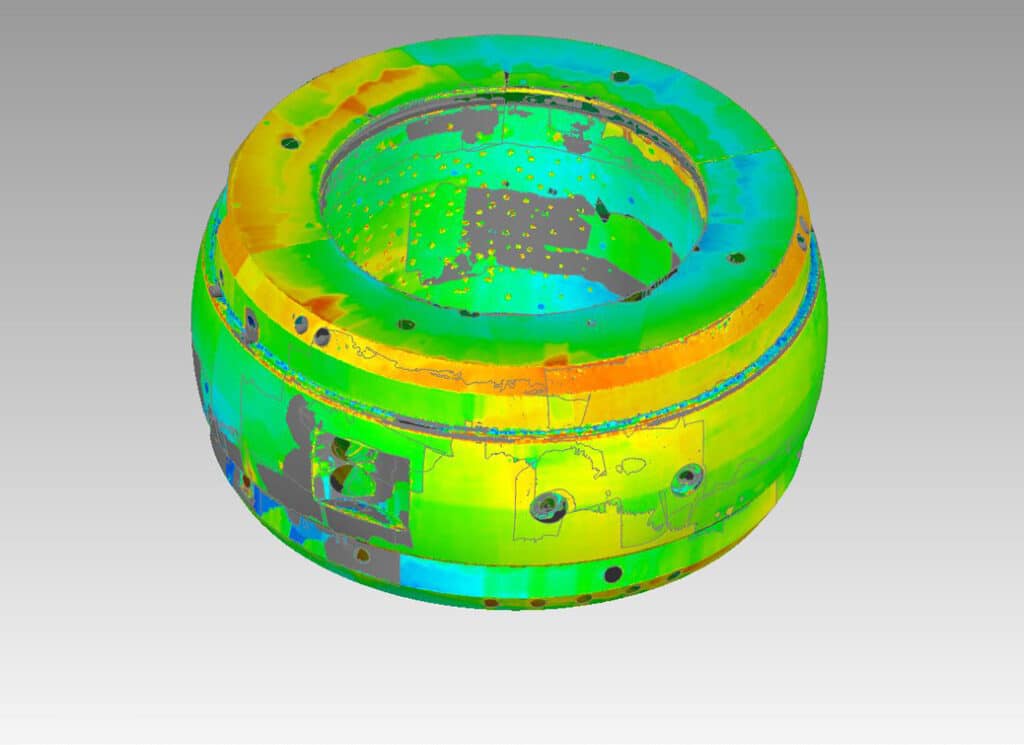

Deformation Analysis

Having a software programmer in the firm allows us to analyze scanned data of an existing object and compare it to design. This is very useful when you need to know where and by how much an object differs from the design, and it is the best way to determine the quality and repeatability of a manufacturing process. We have a range of standard reports for common geometry (Planes, Cylinders, Spheres, Cones, etc.), and we also provide complex comparisons against objects like Pressure Vessels, Piping, Structural Steel, etc. We work closely with our clients to understand their specific needs and develop custom solutions that meet those needs. We also offer a wide range of value-added services. With our software programmer’s expertise, customization is limitless.

Reverse Engineering

With extensive experience in automotive design, manufacturing, and assembly, we excel at solving complex 3D problems. We regularly collaborate with companies in 3D printing, CNC milling, yacht design, automotive design, tooling, and mold making, which has sharpened our skills and enabled us to develop efficient solutions to a wide range of challenges. Our team of experienced engineers and designers is passionate about helping our clients to achieve their business goals. We work closely with our clients to understand their specific needs and develop custom solutions that meet those needs. We also offer a wide range of value-added services, such as 3D scanning, point cloud analysis, and custom software development.

Deformation Analysis

Having a software programmer in the firm allows us to analyze scanned data of an existing object and compare it to design. This is very useful when you need to know where and by how much an object differs from the design, and it is the best way to determine the quality and repeatability of a manufacturing process. We have a range of standard reports for common geometry (Planes, Cylinders, Spheres, Cones, etc.), and we also provide complex comparisons against objects like Pressure Vessels, Piping, Structural Steel, etc. We work closely with our clients to understand their specific needs and develop custom solutions that meet those needs. We also offer a wide range of value-added services. With our software programmer’s expertise, customization is limitless.